Moisture is a consideration in almost every flooring installation, especially in basements. Concrete is a porous material which means it has extremely small holes that allow moisture from the ground to pass through. If a flooring susceptible to water damage, like laminate, is installed over concrete, then the excess moisture can cause warping and damage to the click-lock system.

Underlayments, vapor barriers, and underlayments with vapor barriers are used to protect the flooring from moisture. In this article we will discuss how different types and materials of underlayment protect your flooring from moisture.

Plastic (6 mil Vapor Barriers)

6 mil vapor barriers are the “go-to” when it comes to potential moisture problems. It creates a waterproof barrier between the concrete and the floor. Even though the plastic material the barrier does not support mold and mildew growth, it is still possible. If mold begins to grow under the vapor barrier it will not cause any issue because if installed correctly it will have an air and moisture tight seal. The mold could potentially become an issue and a health risk if and when you choose to remove the barrier. This is why it is important you make sure the installation site is clean and free of contaminates.

Fiber/Felt Underlayment

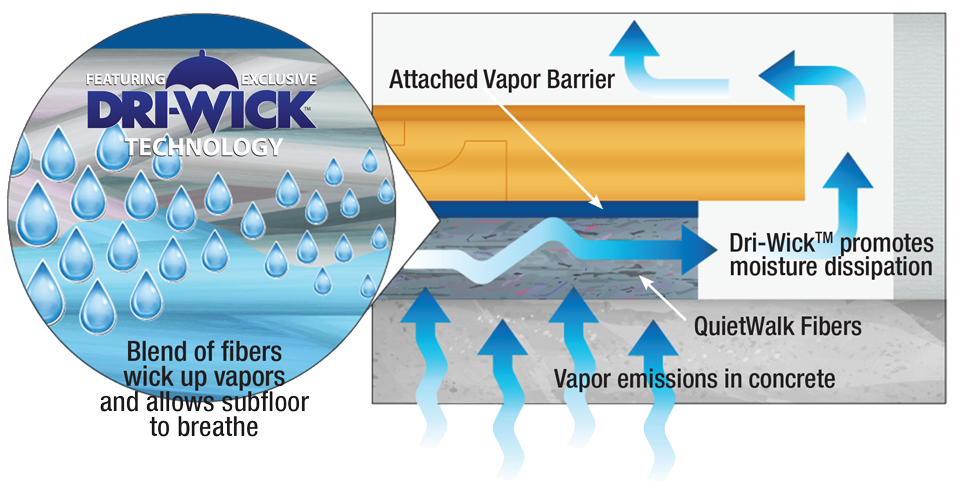

Fiber/Felt underlayments are very good choices of underlayment because of their exceptional R-values, noise dampening properties, and compression resistance. Fiber/Felt underlayments are not waterproof. However, they allow the concrete to breathe by letting the pad soak up the moisture from the subfloor. This may seem like a bad idea, but a thin vapor barrier is attached on top. The vapor barrier protects the overlying floor while the moisture slowly dissipates out a small gap left when installing the underlayment. QuietWalk’s Dri-Wick Technology is an example of this system implemented exceptionally well.

Cork Underlayment

Cork Underlayment is water resistant, but it is not waterproof. As of right now there is no natural cork underlayment with a moisture barrier attached. This means when installing on a subfloor where moisture may be a problem it is best to use a 6 mil plastic vapor barrier.

Paper Underlayment

Paper underlayment may sound a little odd when you first hear it. However, fortifiber laminates two layers of Kraft paper with asphalt creating their “Aquabar B“. This underlayment performs very similar to the way plastic 6 mil vapor barriers perform. It is designed to only control the moisture problems. It does not provide much cushioning or sound reduction.

Foam Underlayment

Foam is the most common material used by underlayment manufacturers. It gains its popularity since it is cost-effective to manufacturer. As for water resistance and water proofing, different materials the foam is made out of will affect the foams ability to stop water.

Polyethylene is the first type of foam we will consider. Polyethylene (poly) IS permeable to water. This means water will slowly go through the poly, but the thicker the poly, the slower the water will transfer through. The common rule of thumb is 6 mil as vapor barrier is a good minimum thickness to use for a vapor barrier.

So an underlayment over 6 mil thick and it’s material listed as polyethylene means it is an adequate moisture barrier for all concrete subfloors right? Not quite. Just because the material is listed as polyethylene doesn’t mean that it is a vapor barrier of polyethylene. There is usually other materials in the underlayment to provide cushion which means it will be more permeable to water. The foam has a value and the attached “moisture barrier” film has a value, combining to give the product its overall value.

Polypropylene has a permeability half that of polyethylene so 3 mil polypropylene would be equivalent of 6 mil polyethylene. Polypropylene is a less common foam underlayment material.

Polystyrene has the highest permeability out of the three materials. For underlayment made from this material, it important that you pay close attention to the water vapor transmission rate if there is one listed. If they do not list the vapor transmission rate and do not have an attached 6 mil vapor barrier, it is best to put a 6 mil vapor barrier down to be safe.

Conclusion

Concrete subfloors will cause moisture problems if unprepared for. This is why it is important you know what to look for in an underlayment for moisture protection. All underlayments with vapor barriers should have a water vapor transmission rating (measure of passage of water through a substance). To find out if the rating will be enough for your concrete you should consider doing a calcium chloride test. This test measures how much moisture your concretes puts off in a certain time period. You can then compare your results with the maximum transmission rate of your underlayments vapor barrier to see if it will hold up against your concrete floors amount of moisture. If you want to take care of moisture problems for sure, it is best you install a 6 mil vapor barrier with your underlayment or find an underlayment with a 6 mil vapor barrier already attached.